Ajax Mobile Loading Hopper for Pharmaceutical Production.

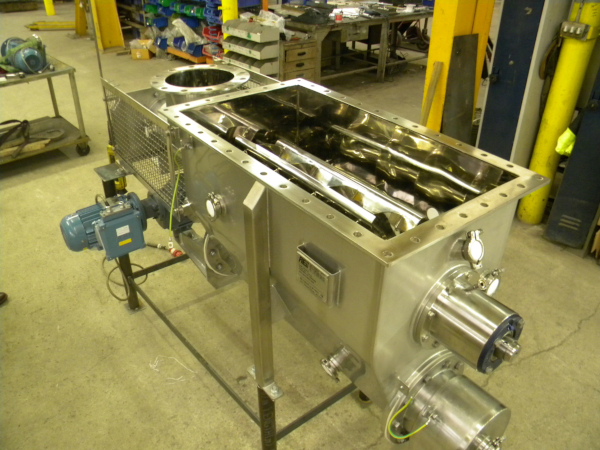

Solids handling equipment specialist, Ajax Equipment, has supplied a leading pharmaceutical company with a fully passivated mobile loading hopper with hinged lid and transition chute. The equipment is designed to handle and transfer pharmaceutical powder from a drum under gravity flow in an ATEX zone 21 area.

The equipment was fabricated in grade 316 stainless steel with all contact surfaces mirror polished and contact welds made crack and crevice free; the finish promotes flow and discourages any possible build-up of powder. The design was informed by powder testing carried out by Ajax onsite in Ireland. Assessment of the material enabled Ajax to produce a hopper and transition chute that works with the poorly flowing powder as well as effectively interface with the site’s existing mill.

The hopper’s construction is fully passivated, ensuring the integrity of the stainless steel finish. In addition, the hopper is mounted on a mobile frame including hygienic, anti-static wheels allowing for flexibility in plant configuration as well as enabling the hopper to be moved for cleaning when required. The loading hopper is designed for ease of operation while in a protective suit and includes features such as a counterbalanced lid.

“Pharmaceutical processing is one of the most demanding industries in terms of the quality of finish required; Ajax has over 50 years’ experience of working with pharmaceutical companies, producing equipment that meets a range of industry standards,” said Eddie McGee, managing director, Ajax Equipment.

For more information on Ajax Hoppers, call +44 (0)1204 386723 or visit our

Hopper Design page.

Solids handling equipment specialist, Ajax Equipment, has supplied a leading pharmaceutical company with a fully passivated mobile loading hopper with hinged lid and transition chute. The equipment is designed to handle and transfer pharmaceutical powder from a drum under gravity flow in an ATEX zone 21 area.

Solids handling equipment specialist, Ajax Equipment, has supplied a leading pharmaceutical company with a fully passivated mobile loading hopper with hinged lid and transition chute. The equipment is designed to handle and transfer pharmaceutical powder from a drum under gravity flow in an ATEX zone 21 area.