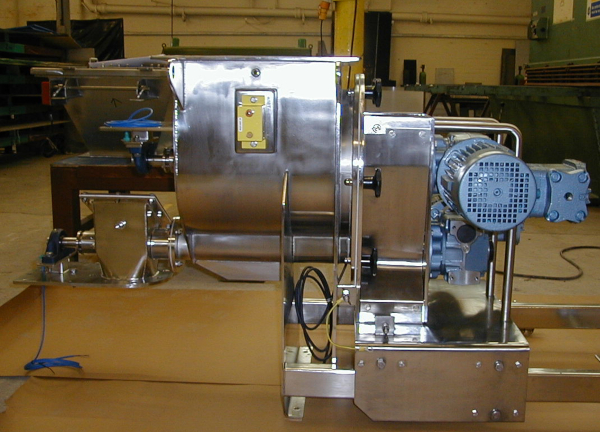

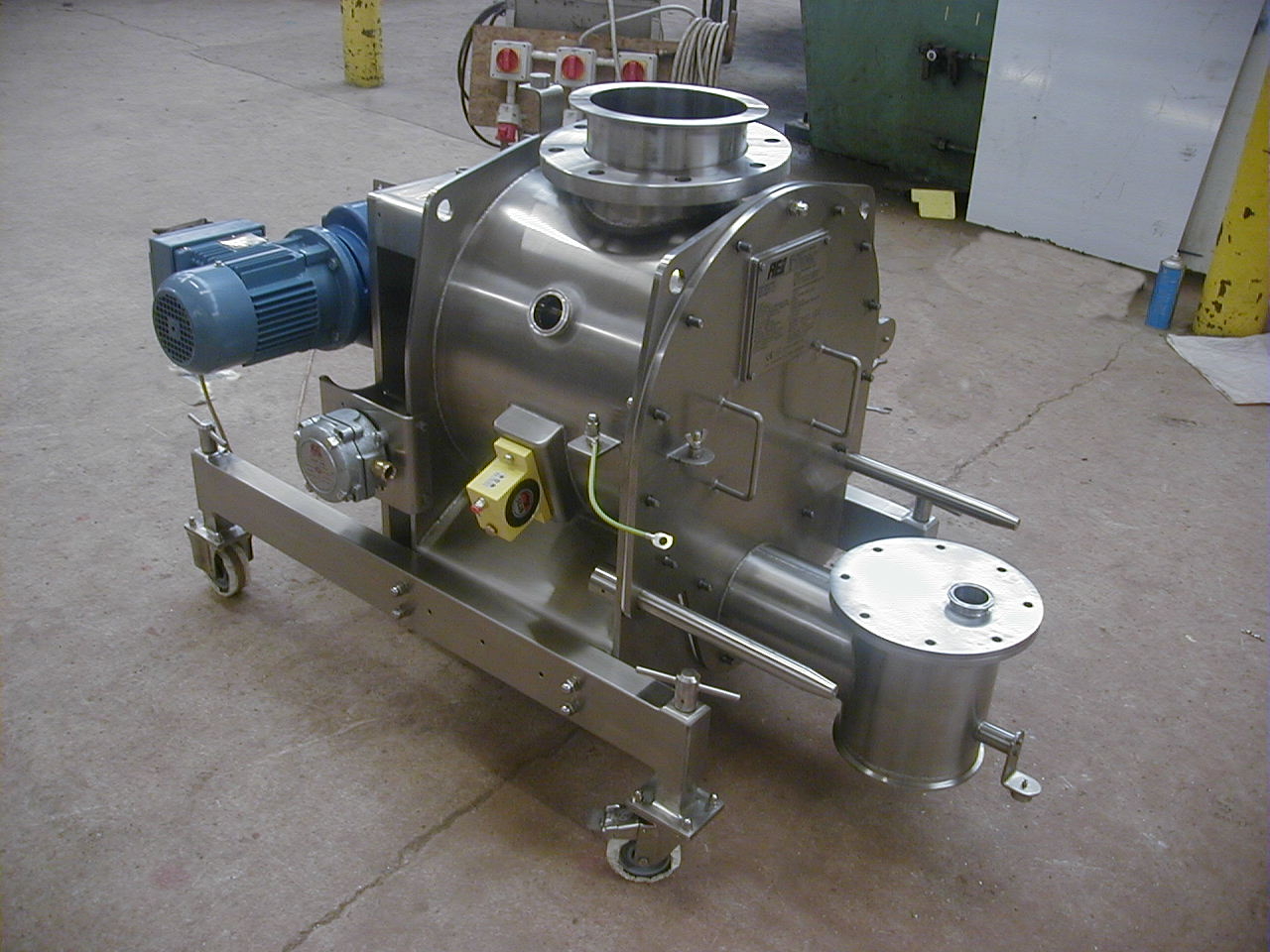

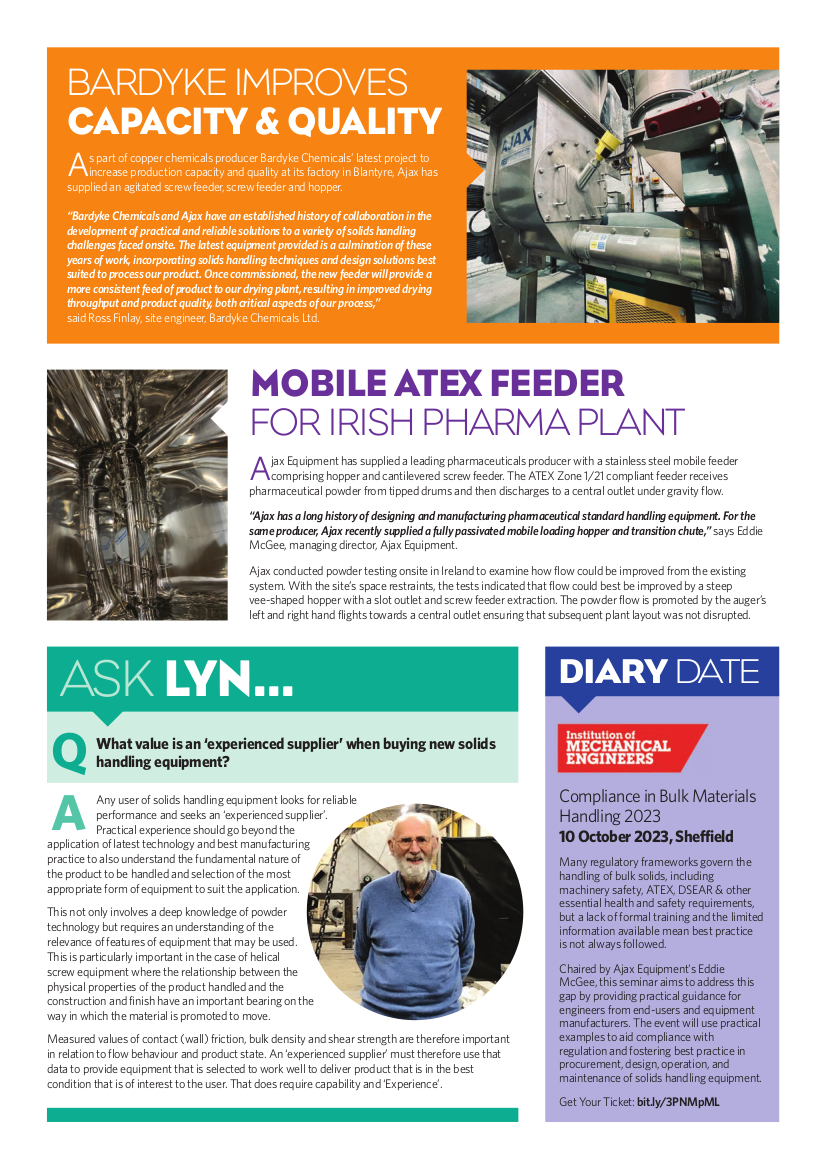

Screw feeders for powder and bulk solids handling. Products include gravity flow feeders, agitated feeders, multiple screw feeders and hopper and feeder combinations.

44 (0)1204 386723

sales@ajax.co.uk

sales@ajax.co.uk

Customer

Testimonials

Testimonials

Products

Page

Page

Solid News

Newsletters

Newsletters

Company

Brochures

Brochures