AJAX Plug Screw Feeders

Plug Screws for Pressure and Temperature Barriers

A common problem in solids handling is to isolate the feed stream from final ambient conditions pertaining in the delivery region. Whether due to adverse temperature, moisture, vapours or pressure differentials it is often necessary to provide a positive seal for protection of the product, equipment or of the initial atmosphere, between the conditions from where the feed stream is drawn and those at the point of delivery.

Likewise, the containment of dust, gasses, exclusion of contaminants or other reason for sealing the receiving point frequently demand the inclusion of a device to provide positive sealing in the feed system. Rotary valves, double flap valves and lock hoppers are included for this purpose.

Apart from considerations of cost and space such extra equipment frequently introduces secondary problems of wear, residue deposits, flow restraints and blocking. Some devices interrupt the continuous flow of material by way of delivering discrete pockets or batches of product.

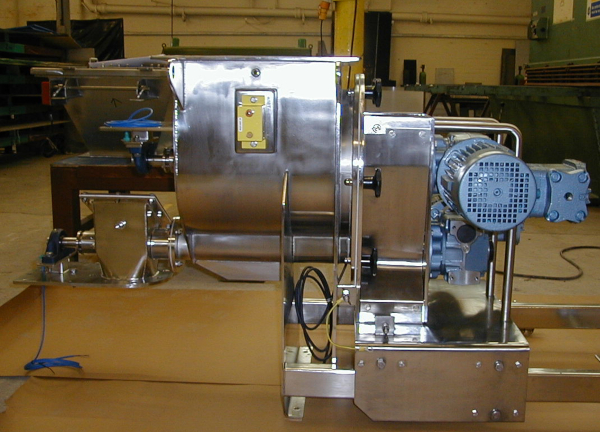

An elegant solution to this problem may be secured by the use of Ajax Plug Seal Screw Feeders. These accessories can be incorporated in Ajax Feeders of Standard and Custom Design.

A range of Ajax Screw Feeders are made with a type of cantilever mounting screw construction. This arrangement carries a raft of benefits:-

Only one shaft end seal.

Direct, unobstructed end discharge.

Pressure injection possible.

Easy-clean retractable Screw assembly.

Integral delivery end seal available.

To these virtues, there is the added facility to incorporate a LynFlowTM Plug Seal, using the product being fed to block off the flow channel between the supply and delivery point. Material fed forward by the screw is compressed to occupy the whole cross section of the screw casing.

It must be emphasised that this technique is not a panacea for all sealing problems.

Each application requires individual technical evaluation and its prospect depends upon the nature of the bulk material and the operating conditions to be encountered.

However, a properly designed Plug Seal is compact, simple and capable of long service with minimum attention. This technique merits close inspection for difficult feeding applications.

For more information on Ajax’s screw feeders, call +44 (0)1204 386723 or visit our Screw Feeder page.