Solids Handling and Processing for the Chemical Industry

Ajax Equipment has over 55 years’ experience working with leading chemical companies around the world, supplying a range of solids handling and processing equipment including hoppers, screw feeders, agitated screw feeders, screw conveyors, batch & continuous mixers, screw elevators and lump breakers to improve and expand production.

A material led approach means Ajax’s equipment is designed to work with your bulk solid, leading to better handling or processing performance.

Examples of Ajax’s projects with the chemical industry include:

Bradley Pulverizer

Ajax’s “Magic Solution” Improves Silo Flow Reliability & Feed Stability

In response to feed variations in excess of 30% at an Egyptian fertiliser plant handling milled phosphate, Bradley Pulverizer called Ajax Equipment in to investigate. After conducting powder testing Ajax recommended replacing the bottom section of the hopper, including a hopper insert to promote flow, as well as the addition of a twin screw feeder to ensure material was drawn from the full width and length of the new hopper outlet.

Since installation of the new hopper section and integral screw feeder the performance of the process has improved significantly; no longer do flow stoppages or unexpected flushing upset the process as the twin screws deliver a stable and consistent feed, allowing the plant to produce the high quality product at the nameplate rates desired.

Lianhetech Europe

Keeping a Highly Corrosive and Cohesive Product on the move

Each material has its own requirements, but some require extra care when handling. Due to the corrosive properties of the centrifuge material Lianhetech Europe was working with, Ajax suggested constructing the agitated screw feeder required in Alloy 22, an extremely corrosion resistant high nickel alloy.

The agitated feeder receives batches of product into its hopper section fitted with a multi-bladed agitator that sweeps the internal diameter and along the full length to disturb time consolidation, as well as sweep product into an integral LynFlow™ ribbon screw feeder that extracts along the full length to regulate feed into the site’s dryer. The agitated feeder is ATEX compliant for Zone 1/21, category 2 equipment (inside and out) with N2 purge and was water fill tested as part of successful Factory Acceptance Tests at Ajax’s works.

Johnson Matthey

Screw Conveyor Enhances Catalyst Production

In 2024 Ajax Equipment supplied speciality chemicals company, Johnson Matthey, with an inclined screw conveyor and chute sections to enhance the handling of a catalyst material at temperature.

Since the screw conveyor is operating at an incline, the machine includes a range of features to ensure effective material transfer and mitigate any material fall back. The conveyor’s flights were manufactured in a smooth finish of stainless steel as material testing by Ajax indicated this would provide better slip and material transfer than mild steel. In addition, screw geometry was selected with flights that compensate for the angle of operation. To limit the impact of material fallback on effective transfer, each section of the screw conveyor’s covers has a special profile.

Bardyke Chemicals

Expanding Copper Chemicals Production

Ajax has worked with Bardyke Chemicals over many years to increase production capacity and process reliability at its Blantyre factory in Scotland. In 2023, Ajax supplied Bardyke Chemicals with a range of equipment including hopper, screw feeder and agitated screw feeder to provide a more consistent feed of a damp chemical filter cake to the company’s drying plant.

The hopper’s vee shape encourages flow of material towards the integral single screw feeder below, while the feeder’s progressive flight geometry helps extract material from the hopper as well as provide a controlled feed of powder to the agitated screw feeder. Agitated screw feeders, a combination of hopper, agitator and feed screw, are well suited to ensuring damp cohesive materials, such as this, are kept in the required condition and then positively transferring them.

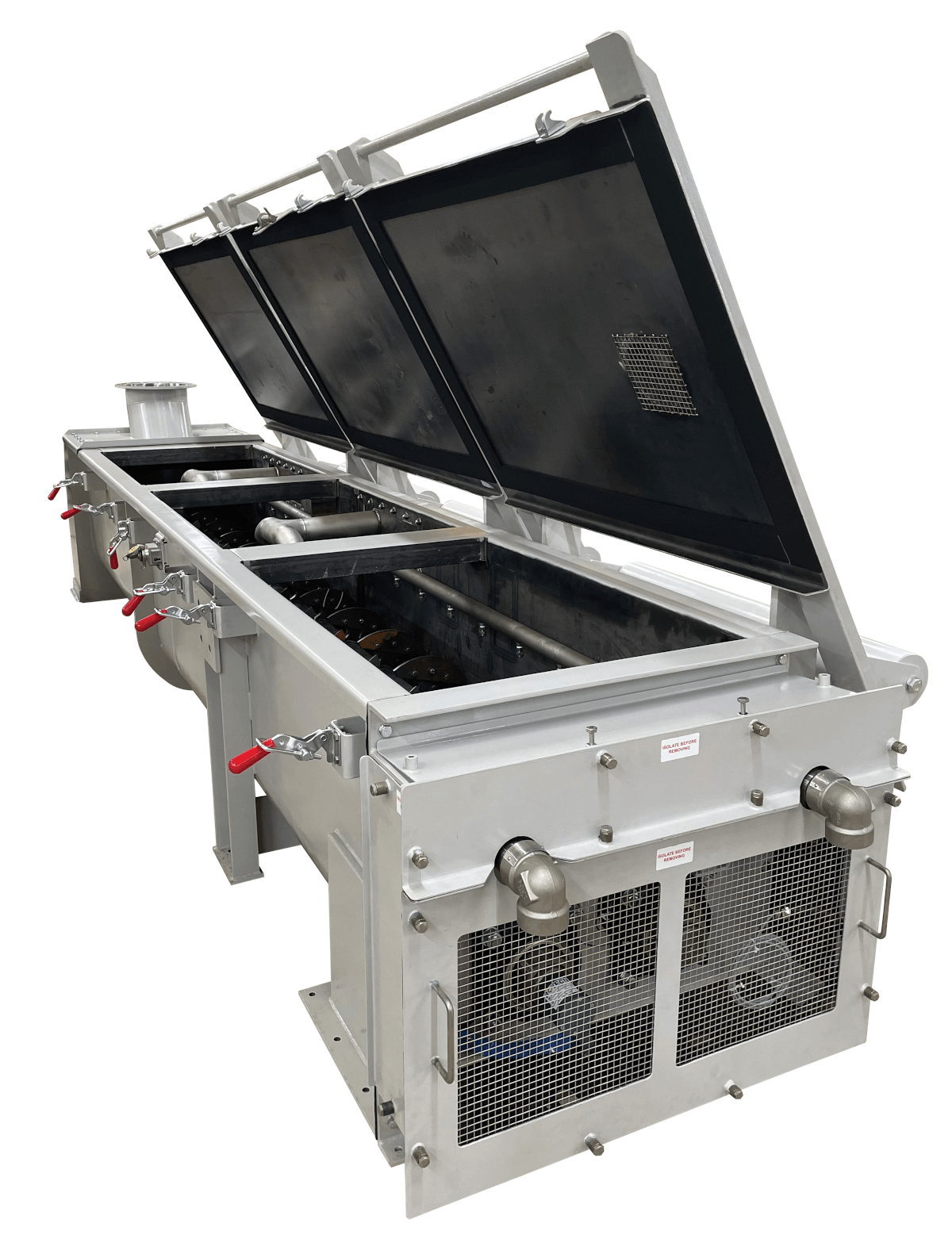

Vertellus Speciality Materials

Large Agitated Screw Feeder keeps Centrifuge Cake Flowing

In 2016 leading speciality chemicals producer, Vertellus Speciality Materials, was upgrading its Teesside, UK plant for a new product. Following the reliable performance of an existing agitated screw feeder produced by Ajax, Vertellus returned to Ajax for a significantly higher capacity agitated screw feeder, capable of holding several tonnes of damp centrifuge cake; at the time the largest agitated screw feeder Ajax had produced.

The stainless steel unit has a large capacity hopper with multi-bladed agitator which provides gentle agitation to maintain ‘live’ product condition, disturbs any potential consolidation and delivers positive infeed to the integral screw feeder. Once discharged, the cake is transferred to two dryers via an Ajax long screw conveyor. Special care was taken in outlet and screw design to ensure output goes to the appropriate dryers. The screw feeder and conveyor both feature LynFlow™ ribbon flights which inhibit adhesive materials from clogging up the screw.

Intersurgical

Getting to grips with Waste Processing

When leading respiratory medical device designer, manufacturer and supplier, Intersurgical, was looking for a fast and effective method of dealing with increased volume of set lime and phosphorous an Ajax mobile lump breaker was selected.

The stainless steel lump breaker features an integrated control panel and a high standard of safety features. The mobility of the equipment allows the operator to locate the equipment near to the source material. The unit also features sliding safety gates to restrict side access to the discharge area during operation, and the integral holding hopper and hinged cover is fitted with safety features including Rotacam safety switches.

Kemira Chemicals

Setting the Standard for Mixing & Feeding

Over several years Ajax Equipment has worked with leading water chemicals company, Kemira Chemicals, on various upgrades to enhance the production of dry polyacrylamide at the company’s Bradford plant.

For one upgrade Ajax supplied Kemira with four high capacity vertical screw blenders. Following this, Ajax supplied a further two blenders when Kemira decided to standardise on the Ajax mixer. Mixer design was challenging due to the small footprint and limited headroom available. To provide maximum capacity as well as high re-circulation rate and mixing efficiency, Ajax used central ‘fountain’ type mixing augers featuring special taper design with increasing pitch and taper reducing centre cone – the latter being critical in generating an effective mixing pattern within mass flow transition shape to the blender body.

As part of another project Kemira installed several Ajax screw feeders transferring polyacrylamide granules to replace troublesome vibratory feeders. Kemira not only improved plant reliability with the Ajax screws but also enhanced output by filling IBCs quicker and more accurately.

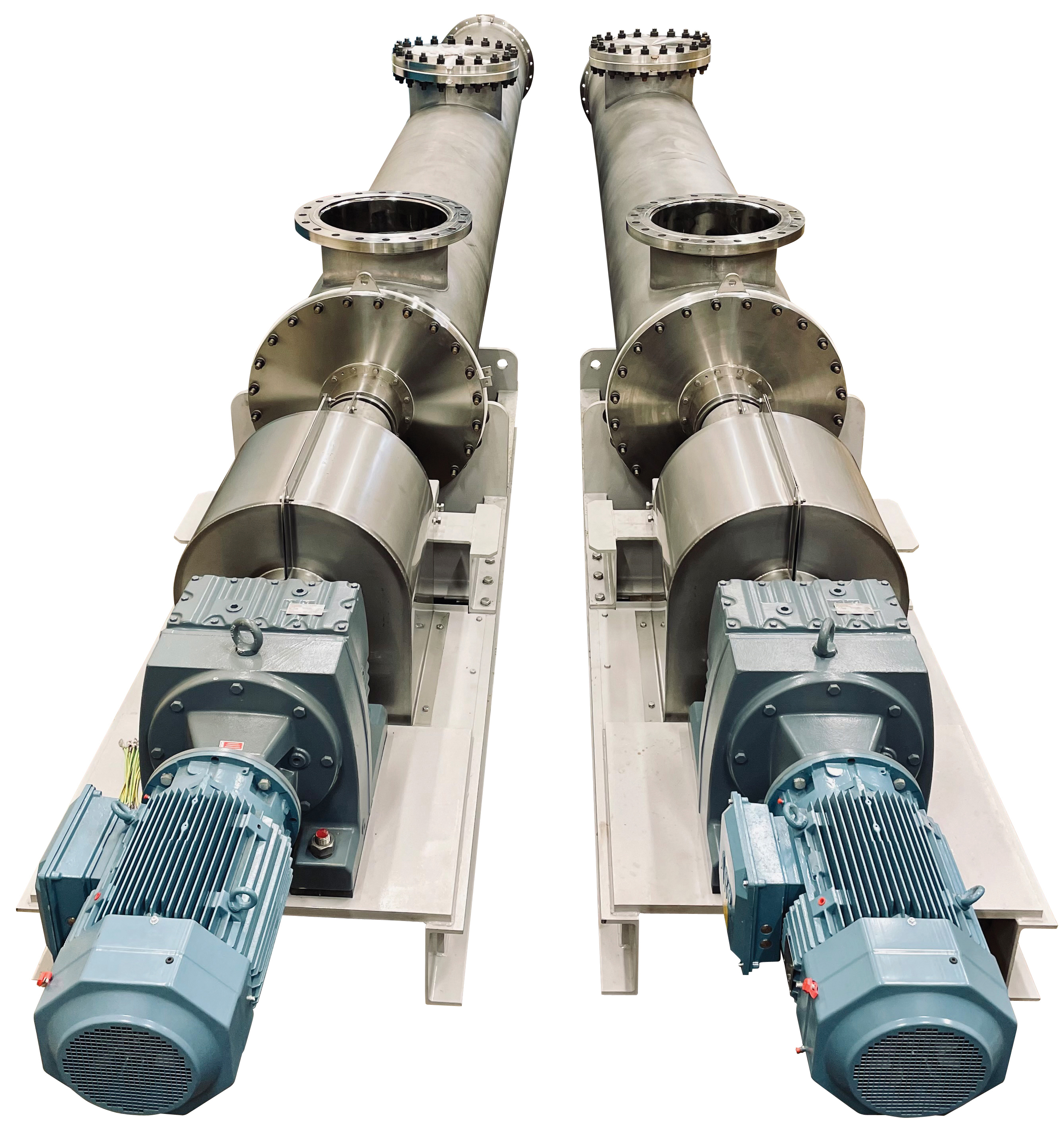

Indorama Ventures Quimica

Supersized Screw Conveyors Boost Polymer Powder Handling

Leading chemical producer, Indorama Ventures Quimica, is using two stainless steel horizontal screw conveyors sharing a common discharge chute from Ajax for handling semicrystalline polymers at its Cadiz production site in Spain.

The complex production process demanded the equipment be designed to ASME 8 and PED category 4 – module G, and therefore design and manufacture has been under the authority of a UK/EU Notified Body. The Ajax screw conveyors utilise LynFlow™ ribbon flights, designed to provide excellent powder transfer and prevent product build-up. This unique flight form allows for process gas flow through the system. As the conveyors share a common discharge chute, equipment fit up with both angular and vertical offsets had to be accommodated, however, this challenging configuration was well met by Ajax.

For more information on AJAX’s equipment for chemical applications please see the links below:

Hopper and Twin Screw Feeder for Bradley Pulverizer

Ajax Agitated Screw Feeder for Lianhetech Europe

Ajax screw conveyor enhances handling at Johnson Matthey

Ajax Equipment Powder Handling System for Bardyke Chemicals Expansion

Ajax's Large Agitated Screw Feeder for Chemicals Manufacturer

Ajax mobile lump breaker for Respiratory Care Product

Kemira Chemicals 'Standardises' on Ajax Batch Mixers

Clariant Increases Leather Process Chemical Production with Innovative Ajax Conveyor

Ajax Equipment LynFlowTM Ribbon Screw provides the solution when a standard screw conveyor clogs with filter cake

Ajax's Large Agitated Screw Feeder for Chemicals Manufacturer

Ineos Fluor selects AJAX Equipment for Hydrofluorocarbon Plant Contract for Hydrofluorocarbon Plant Contract