Handling and Processing for the Food and Confectionery Industries

Ajax Equipment has supplied a range of solids handling and processing equipment including hoppers, feeders, mixers and lump breakers to leading food, confectionery and beverage manufacturers throughout Europe, USA, Australia, Asia and the Americas.

Ajax’s equipment for food and confectionery production has been developed to be compliant with EU Hygienic Design standards, including BS EN 1672-2 (2005) and EHEDG. All of Ajax’s equipment is designed for best performance, reliability and ease of maintenance as well as cleaning.

Examples of Ajax’s equipment include:

Hoppers and Feeders

Cocoa Powder Handling

Ajax has designed and supplied hoppers with integrated screw feeders with flow enhancing geometry and construction for effectively discharging cocoa powder - one of the more difficult powders for solids handling equipment to handle. A tendency to cake, together with poor flow in its un-milled form, can also make handling difficult unless sufficient attention is paid to ensuring the equipment is designed sympathetically to the powders' flow characteristics. In this way, flow problems caused by 'bridging' over an outlet or rat-hole formation are avoided using Ajax hoppers.

Grain Handling for Distillery

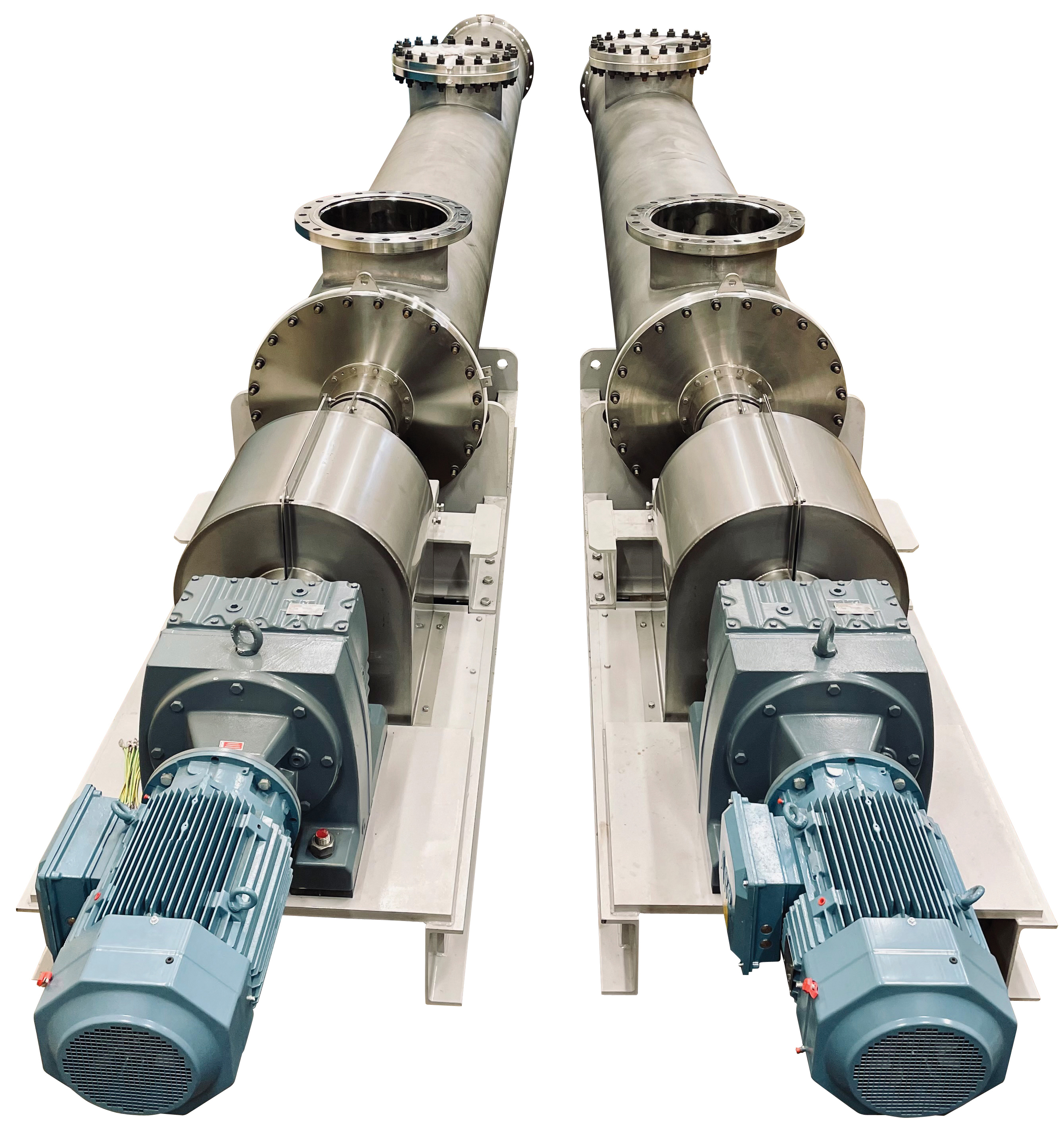

Following flow property tests Ajax supplied Edinburgh’s North British Distillery with a new hopper bottom section as well as a twin screw feeder. The steep 2B stainless steel converging walls form new dual outlets to the twin screw feeder, increasing flow from the existing silo. The new feeder’s larger diameter screws provided greater extraction through variable pitch geometry, as well as increased tolerance of the material’s variability in flow condition

Continuous Mixers

Potato Mixers Expand Capacity

Ajax Equipment has supplied leading European pre-fried and frozen potato product producer, Agristo, with four continuous mixers over several years. The stainless-steel, twin-screw mixers provide efficient though gentle mixing to grated potato and various additives, including flavourings, to produce a range of potato products with negligible damage to the ingredients.

Chocolate Production

Continuous mixers, single and twin screw, are ideal for homogenising chocolate and other pastes as well as incorporating inclusions including toffee, cereals, crispies, nuts, and fruits. The mixers feature a heated jacket and screw shaft to ensure the liquid chocolate maintains the required temperature.

Cereal Bar & Granola Mixing

Ajax has worked with many of the world’s leading food producers on mixers for cereal bars and granola. Ajax offers a range of mixing technologies to provide efficient mixing to a variety of ingredients. Many ingredients commonly used in cereal bar production are sticky and prone to build-up. Ajax’s Lynflow™ flights are designed to prevent these ingredients building-up, reducing the need for cleaning downtime. A hot water jacket can also help maintain material temperature, ensuring consistent ingredient condition and thorough mixing.

Screw Feeders

Sweet Production

Ajax has custom built mobile and adjustable screw feeder for insertion of powders and pastes at a constant and consistent flow rate into confectionery products, as part of continuous production process.

Pork Handling

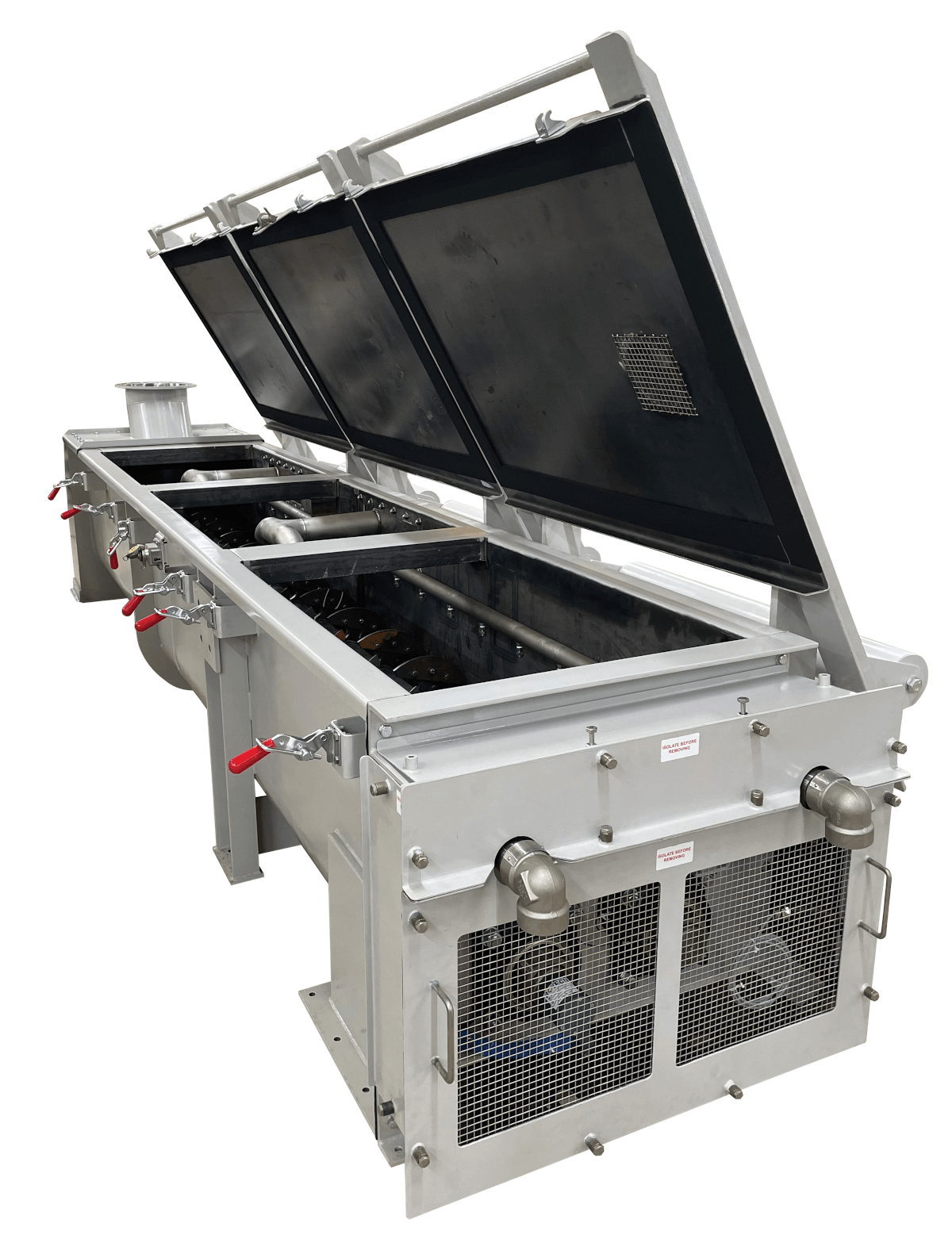

Ajax Equipment supplied Essentia Protein Solutions, a leading protein producer for the food processing industry, with a stainless steel hopper and inclined twin screw feeder to improve throughput, handling and inspection of pork rind. Existing plant suffered from inadequate screw and hopper design and the pork pieces had a tendency to bind together and form a flow inhibiting Truss.

The screw feeder includes several features which enable the equipment to be easily cleaned. A mobile frame allows the feeder to be relocated for cleaning, while Ajax’s special hinged and counterbalanced covers are interlocked to provide safety and security during cleaning. A drop-down end plate arrangement also makes it easy to wash down and safety interlocks ensure operator safety.

Lump Breakers

AJAX lump breakers are ideal for reducing lumps, caked and bag set materials to a consistent particle size for ease of processing. Bespoke models have been supplied for sugar, cassava root and even for noodle nests! Available in low and high-speed versions for hopper and chute feed, the low-speed model is ideal for gentle crushing of brittle material without excessive dust and fines.

For more information on AJAX’s food handling and processing equipment for food applications please see the links below:

Ajax Screw Conveyor for Global Food Ingredients Supplier

Portable Lump Breaker for Food Packaging Specialist, the Alexir Partnership

Ajax Continuous Mixer for Confectionery Production

Ajax Lump Breakers for Sugar Processing

Ajax Range of Continuous Ribbon Flight and Paddle Mixers for Food Production

Ajax Adjustable Screw Feeder for AMP Rose

Continuous mixing improves snack bar quality at Halo Foods

Ajax Inclined Twin Screw Feeder for Pork Rind Handling

Continuous Mixing for Best Selling Confectionery Bar

Please call AJAX on 44 (0)1204 386723 if you have a solids handling or processing application to discuss.