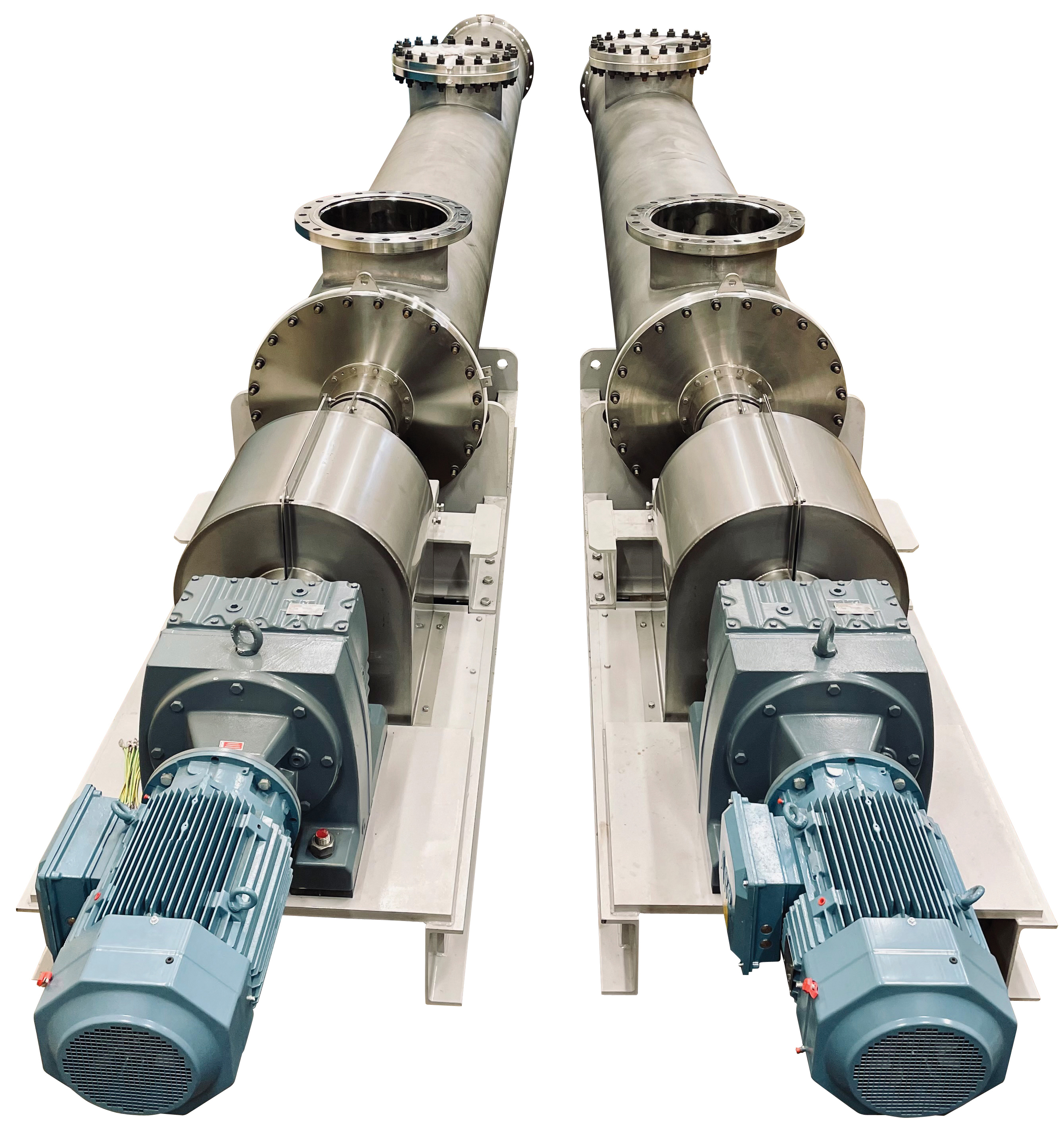

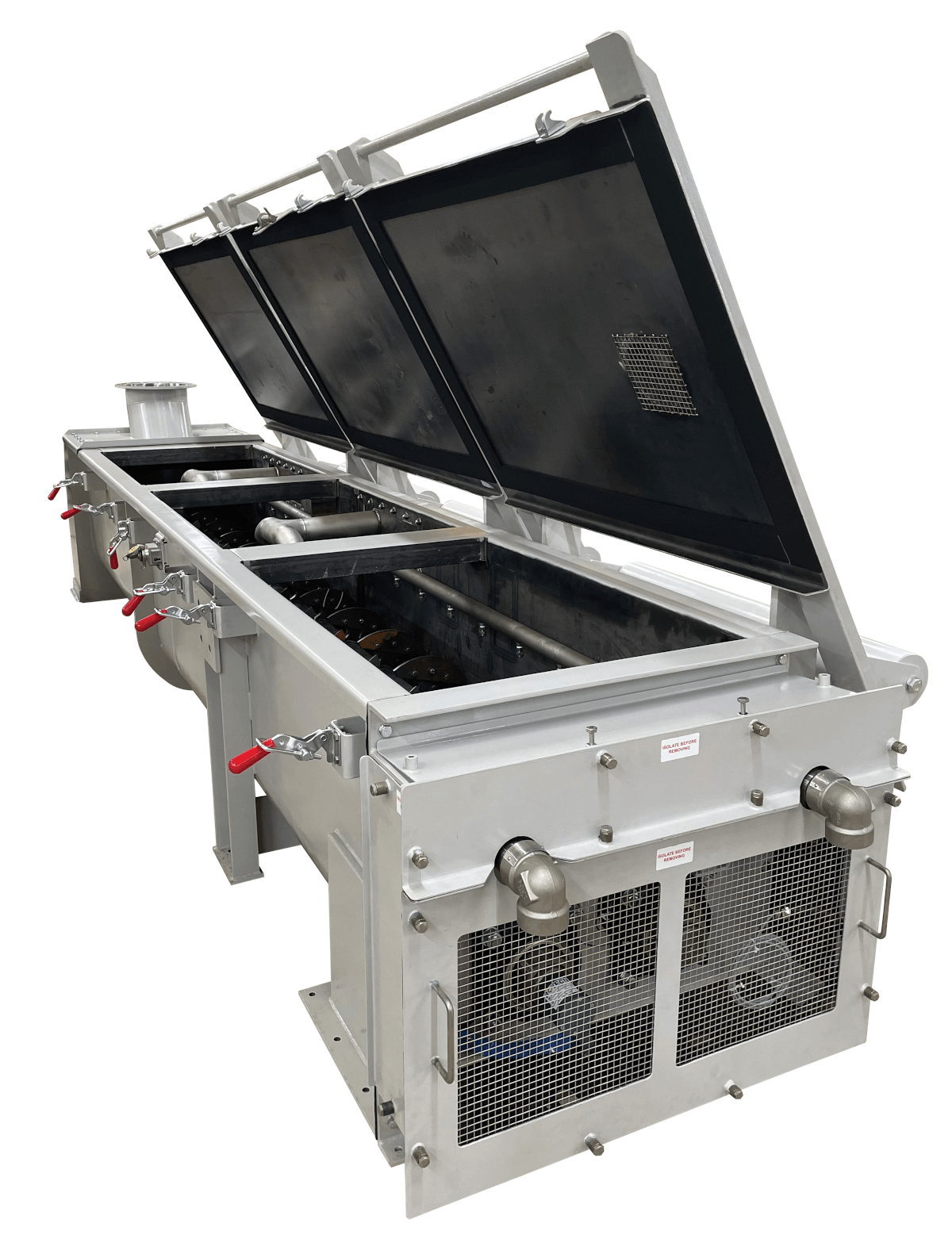

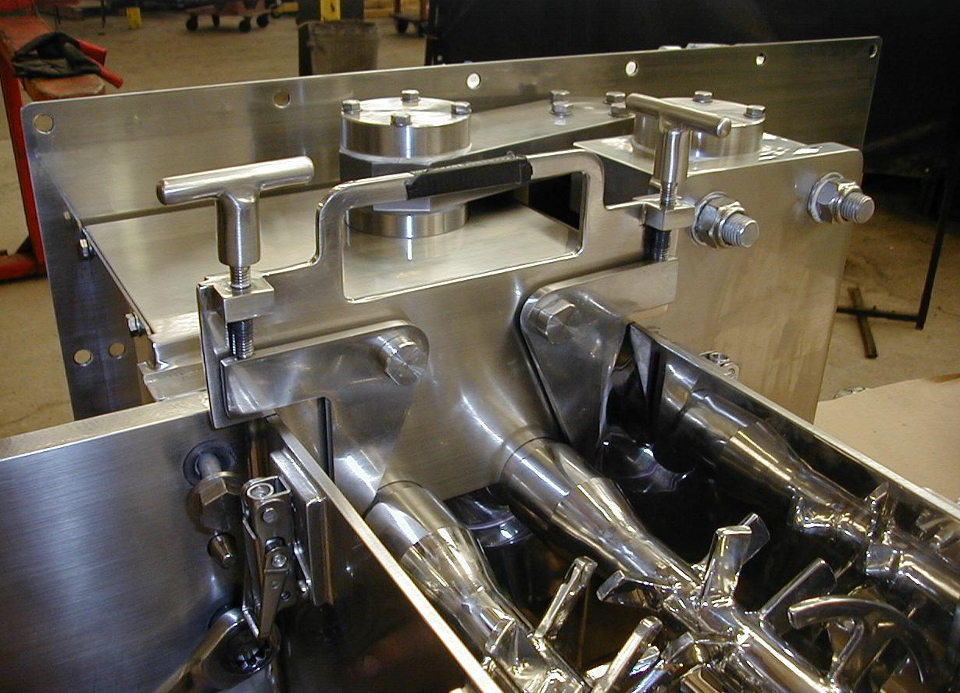

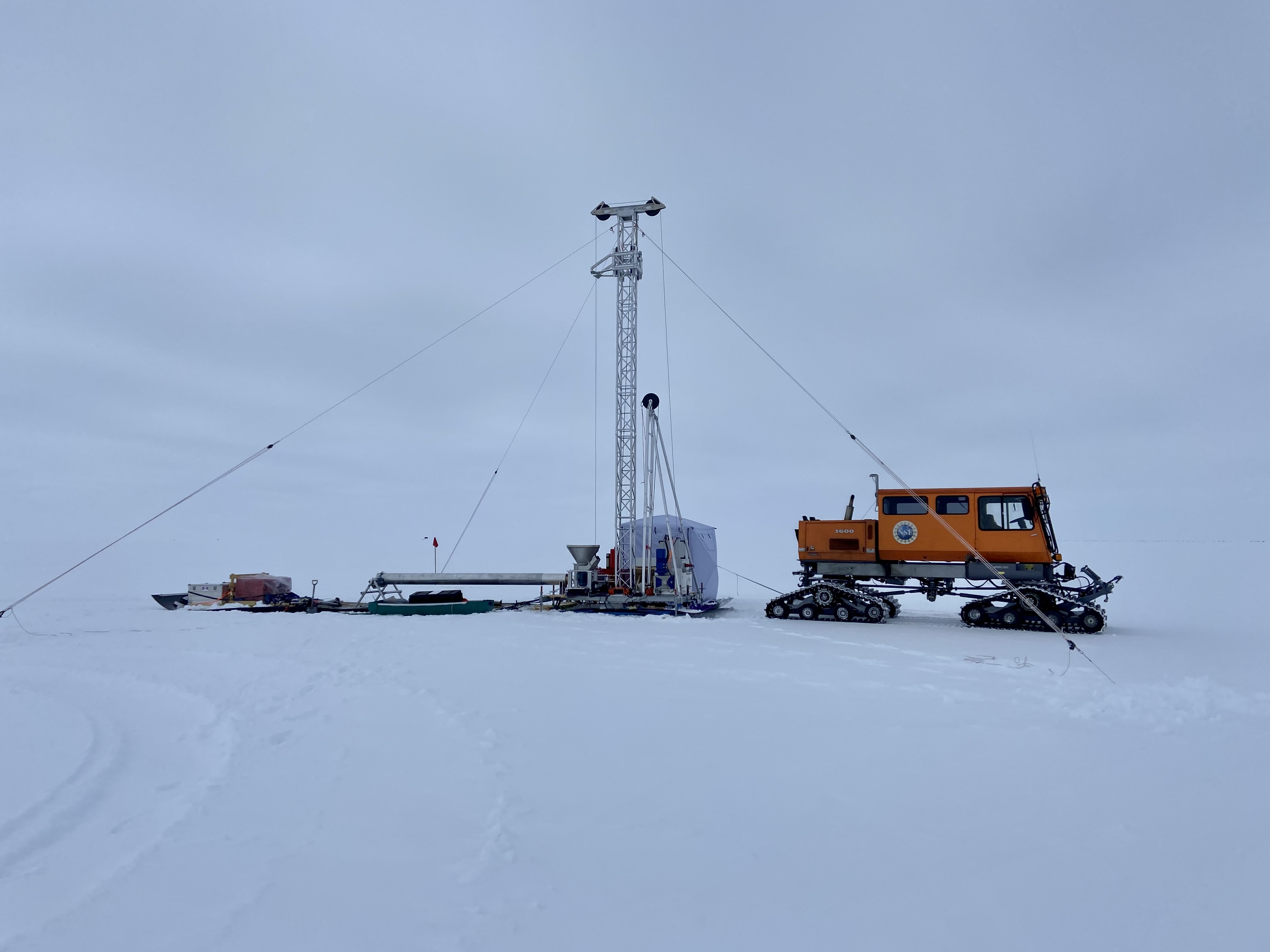

Pharmaceutical standard powder handling equipment including feeders, conveyors, mixers, hoppers, lump breakers, heat exchangers and cryogenic coolers.

44 (0)1204 386723

sales@ajax.co.uk

sales@ajax.co.uk

Customer

Testimonials

Testimonials

Products

Page

Page

Solid News

Newsletters

Newsletters

Company

Brochures

Brochures