Ajax Lump Breakers for Sugar Processing

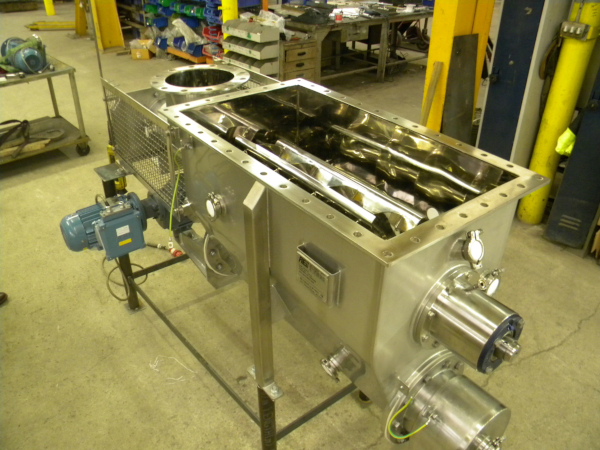

Solids handling specialist, Ajax Equipment, has supplied a process technologies company with two lump breakers for processing sugar. Capable of handling 25,000 kg/hr of granular sugar, the 316L stainless steel, twin shaft lump breakers are designed to ensure the equipment’s internal workings meet ATEX Zone 20.

Highly polished, with a surface finish of 0.8Ra, the lump breakers feature twin shafts with offset cutting blades providing a contra-rotating action drawing lumps into a central breaking zone. Using a twin shaft lump breaker allows material flow to be spread over a larger area.

The lump breakers will be mounted on chute work. FDA compliant seals are used for all joints coming into contact with the sugar. In addition to the equipment’s self-cleaning action, the lump breakers also feature a removable grill, allowing the equipment to be cleaned and thoroughly inspected.

“Ajax has a wide range of experience producing solids handling and processing equipment for food production, including sugar processing. Ajax lump breakers provide reliable size reduction, ensuring consistency in further processing and final product,” commented Eddie McGee, engineering director, Ajax Equipment.

Size Reduction Ajax lump breakers are efficient tools for achieving size reduction with a wide range of materials. Size reduction is carried out for a number of reasons, including preventing damage to equipment and improving the production process. Breaking down ingredients stops mixer paddles from becoming damaged during mixing and ensures blockages of hoppers and feed chutes are avoided.

Size reduction can also benefit the production process by improving and making reaction rates more predictable, enhancing flowability and ensuring consistent bulk

For more information on Ajax’s lump breakers, call +44 (0)1204 386723 or visit our

Lump Breaker page.