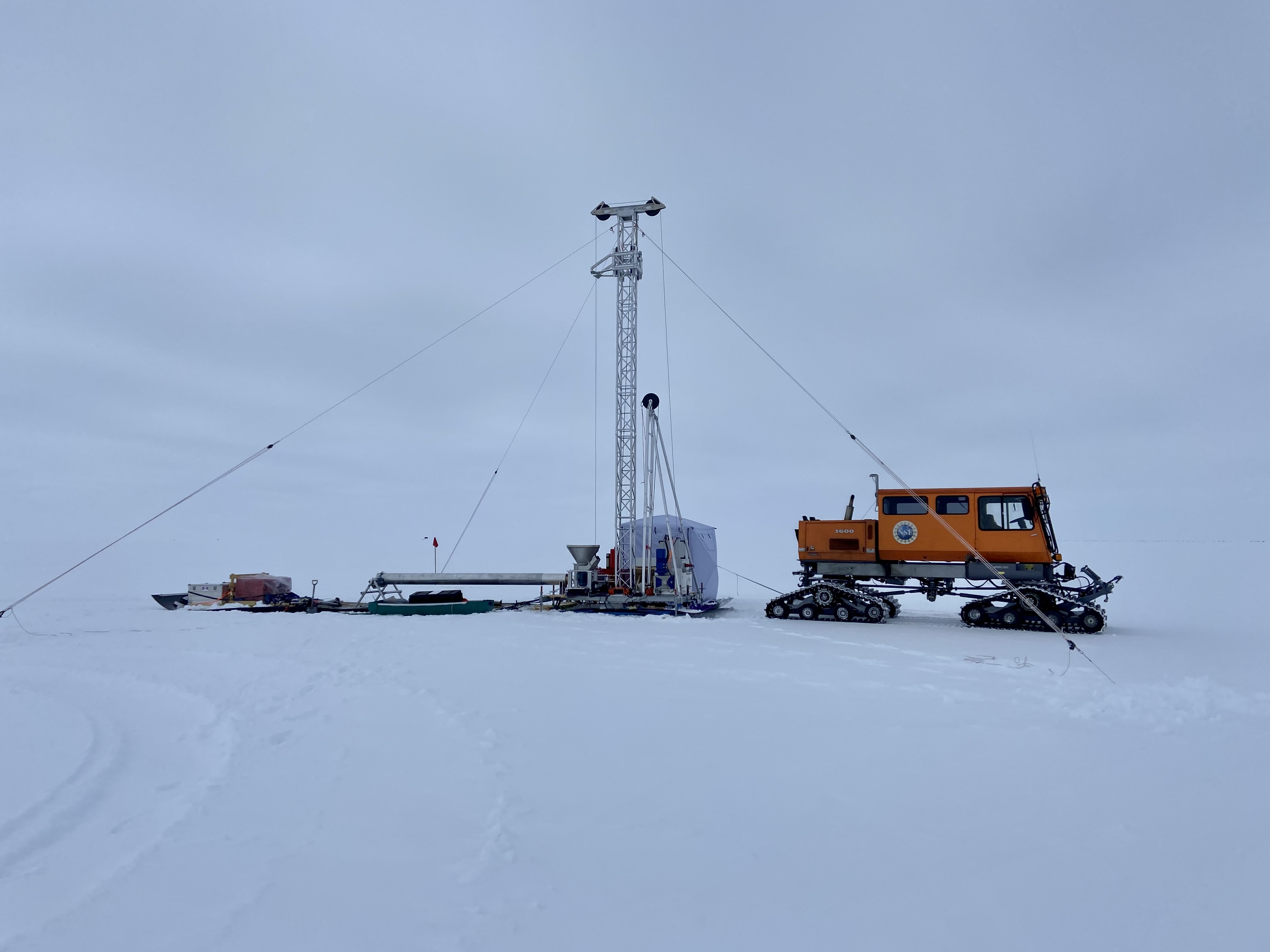

AJAX Twin Screw Feeder for TATA Chemicals

Solids handling specialist, Ajax Equipment, has supplied leading chemicals producer, Tata Chemicals Europe, with a twin screw feeder replacing an existing Ajax twin screw feeder which has reliably performed for over 15 years. Tata Chemicals Europe produce a range of chemicals for the manufacturing, pharmaceutical and food industries. The feeder is used in the production of soda ash at Tata Chemicals' Lostock plant.

The Ajax screw feeder provides a link in production between the centrifuge and fluidised bed dryer. Using a twin screw arrangement with a special outlet provides an evenly distributed feed into the fluid bed. The twin screw feeder is constructed from carbon steel while the auger's ribbon flights are wear resistant steel; the machine requires hard wearing materials due to the effects of soda ash production. The feeder also includes an insulated jacket to maintain the process' desired temperature and prevent condensation. .

"Having worked with Ajax on and seen the benefits of the previous twin screw feeder it was an easy choice to work with them on the new machine. Ajax's knowledge of materials and how to handle them ensures our twin screw feeder is a strong link in the production line," says Martin Philips, Senior Project Engineer - Lostock, Tata Chemicals Europe. .

Commenting, Ajax technical director, Eddie McGee said "Producing soda ash is a tough application, in this case with a high production output as well, because of this all parts of the production line must be of robust design and construction. Ajax supplied the original twin screw feeder in 1994, making updates to the machine in 2000. Combining application based design and careful material selection Ajax's screw feeder has performed reliably for the past two decades and we are confident the new machine will provide the same level of consistency".

For more information on Ajax’s screw feeders, call +44 (0)1204 386723 or visit our

Screw Feeder page.